Table of Contents

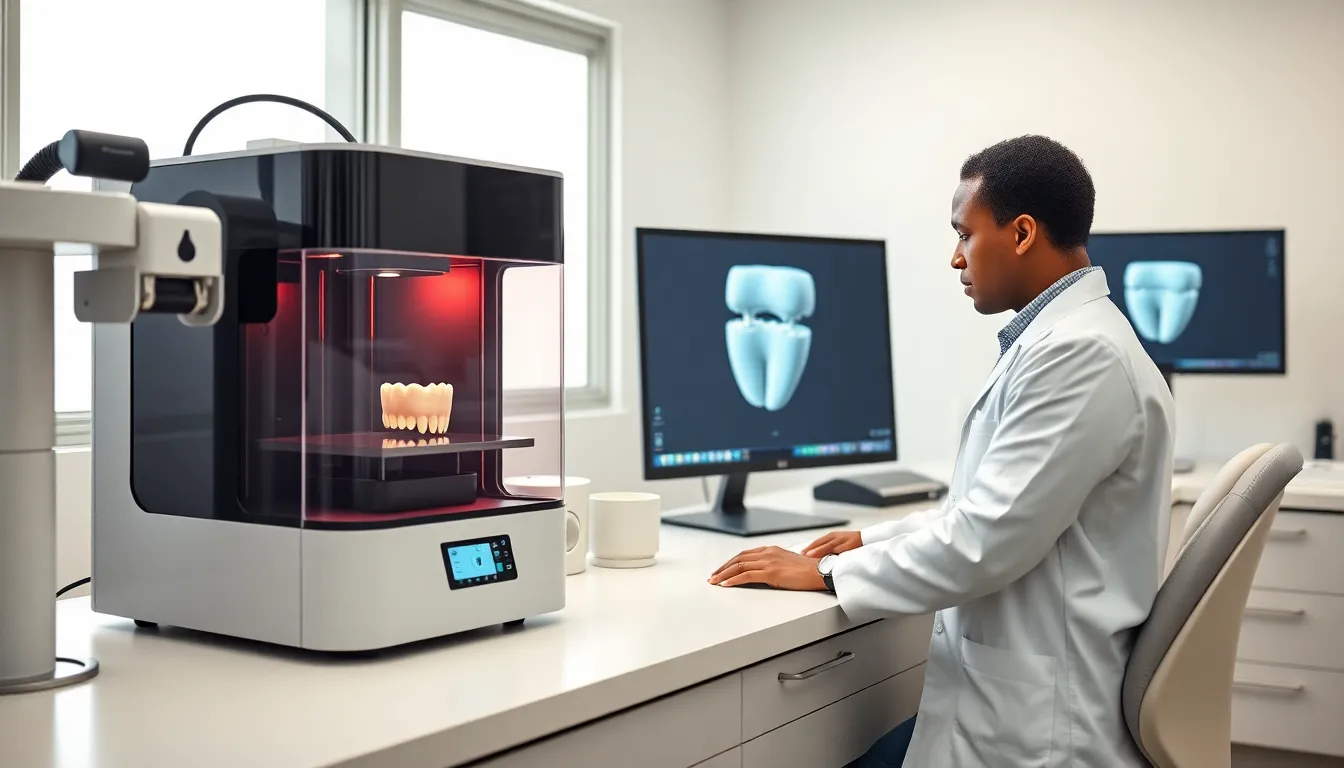

ToggleImagine walking into a dental office and seeing a printer churning out your custom aligners like a futuristic factory scene, it’s not science fiction, but the exciting reality of dental 3D printing. This innovative technology is turning traditional dental practices on their heads, making procedures faster, cheaper, and way more personalized. Ready to jump into how this transformation is taking oral healthcare by storm? Let’s go.

Understanding Dental 3D Printing

At its core, dental 3D printing involves creating three-dimensional objects from digital designs, often using specialized materials tailored for oral applications. Typically, this technology employs methods like stereolithography or fused deposition modeling to build precise dental products layer by layer.

Through scanning, software, and printing, dental professionals can produce custom models that fit patients perfectly. The process often begins with a digital impression of a patient’s mouth, captured through 3D scanning technology. From there, a dental technician designs the necessary item, which might be anything from crowns to orthodontic devices. After digital designs are created, the actual printing process begins, which can take anywhere from a few hours to a couple of days, depending on the complexity of the object.

This meticulous approach not only boosts accuracy but eliminates the need for multiple physical impressions, which means fewer visits to the dentist and a whole lot more comfort.

The Benefits of Dental 3D Printing

The advantages of integrating 3D printing into dental care are hard to ignore. First off, speed is a game changer. Traditional methods can take significant time, with processing, fitting, and adjustments often lingering for weeks. In contrast, 3D printing can deliver custom dental solutions in days.

Then there’s precision. The ability to create highly detailed replicas of a patient’s oral structure results in products that fit better and function properly. This translates to happier patients and improved outcomes.

Cost-effectiveness is another perk. While the initial investment in a 3D printer might be daunting for some practices, the reduction in labor, materials, and time eventually leads to savings that can outweigh those upfront costs.

Similarly, patient satisfaction soars. With quicker treatments, fewer appointments, and custom-fit solutions, patients leave the office grinning, often literally.

Applications of 3D Printing in Dentistry

3D printing has infiltrated various branches of dentistry, proving itself to be remarkably versatile. Here are some standout applications:

Custom Dental Implants

Creating dental implants tailored to individual patients enhances fit and integration. This personalized approach increases success rates and decreases discomfort.

Orthodontics

For braces and aligners, 3D printing is making waves by producing custom-fitted products that cater to specific patient needs, resulting in effective treatment plans with minimal adjustments.

Crowns and Bridges

One of the most time-sensitive procedures, crowns and bridges can be produced swiftly and accurately using 3D printing, cutting down waiting times significantly.

Surgical Guides

By printing precise surgical guides based on a patient’s unique anatomy, dental surgeons can enhance accuracy in procedures, minimizing risks and maximizing outcomes.

Choosing the Right 3D Printer for Dental Practices

Selecting a 3D printer suited for dental applications isn’t a task to take lightly. Important factors to consider include:

Type of Printing Technology

Different printers use various technologies, including SLA (Stereolithography), DLP (Digital Light Processing), and FDM (Fused Deposition Modeling). The best fit will depend on the specific needs of the practice and the dental applications anticipated.

Resolution and Accuracy

The level of detail a printer can achieve is crucial. Dental products often demand high precision, so dentists should look for printers that promise outstanding resolution.

Material Compatibility

Not all printers can use every type of dental material. Hence, selecting a printer that allows for a variety of biocompatible materials expands the practice’s options.

Cost and Support

Keep an eye on both initial costs and long-term support options. Printer manufacturers usually provide training and ongoing support, which can be invaluable for practices new to 3D printing.

Future Trends in Dental 3D Printing

As dental 3D printing continues to evolve, several trends are emerging that will shape the future of this transformative technology:

Bioprinting

The prospect of bioprinting, using live cells to create structures like tissues, could revolutionize the industry further. Imagine not just printing dental implants but potentially entire, live tissue, it’s being researched and often viewed as a game-changer.

Enhanced Materials

The quest for the perfect 3D printing material is ongoing. dental professionals can expect advancements in biocompatible materials that not only function well but also promote healing.

Advanced Software

As technology develops, software used for dental applications will also improve. In the near future, AI and machine learning may analyze data from 3D scans more efficiently, providing highly personalized treatment recommendations at the click of a button.

Challenges and Considerations

Even though its sizable benefits, dental 3D printing comes with its own set of challenges. First, initial equipment costs can be steep, making it a consideration for budget-conscious practices.

Then, there’s the learning curve. Integrating new technology requires training and adaptation, and not every dentist might feel comfortable with modern technology right off the bat.

Regulatory hurdles also linger. Dentists must ensure compliance with local regulations and guidelines, which can often be ambiguous or change over time.

Finally, while the technology has proven to be reliable, ensuring consistency in output quality remains vital. Practices must continually monitor print settings and material quality to avoid discrepancies.